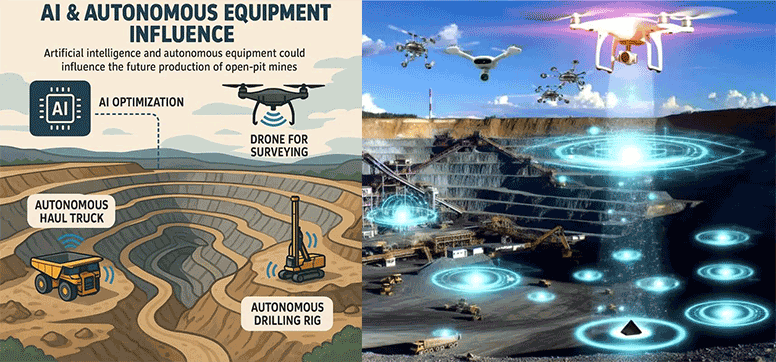

Artificial intelligence and automation: the future of open-pit mining

The mining industry is undergoing a transformation driven by artificial intelligence (AI) and automation. These technologies are not only redefining how open-pit mines operate, but also significantly improving production efficiency, reducing operating costs, and enhancing safety conditions. From intelligent production optimization to autonomous transport, autonomous drilling, and drone mapping, AI and automation are propelling the mining industry toward a more efficient and safer future.

1. Optimizing production with artificial intelligence

AI helps mining companies optimize production processes through data analysis, machine learning, and predictive modeling. For example:

Smart planning systems: AI can analyze geological data, equipment status, and market demand to automatically adjust mining plans and maximize ore recovery rates.

Predictive maintenance: By monitoring equipment operating conditions via sensors, AI can predict mechanical failures in advance, reducing downtime and maintenance costs.

Ore grade analysis: By combining computer vision and spectral analysis technologies, AI can assess ore quality in real time, optimize sorting processes, and reduce resource waste.

2. Autonomous trucks: efficient and safe transportation solutions

Autonomous trucks (such as those from Caterpillar and Komatsu) have become standard equipment in open-pit mines, offering advantages such as:

24/7 uninterrupted operation, unaffected by driver fatigue, improving transport efficiency.

Precise route planning, reducing fuel consumption and tire wear, reducing operating costs.

Increased safety, avoiding collisions or accidents caused by human operational errors.

3. Autonomous drills: precise and efficient blasting preparation

Autonomous drilling systems use AI and GPS positioning to achieve:

Automatic positioning of drill holes to ensure precise blast hole locations and improve blasting efficiency.

Real-time adjustment of drilling parameters to optimize drill life and energy consumption.

Reduced human intervention to reduce the risk of exposure for miners in hazardous environments.

4. Drones for surveying and monitoring

Drones (UAVs) are increasingly being used in open-pit mines, including:

High-precision 3D modeling: Quickly generate mining topographic maps using LiDAR and photogrammetry to help plan mining progress.

Slope stability monitoring: Drones regularly scan rock walls, with AI analyzing cracks and movements to warn of landslide risks.

Inventory management: Measure ore pile volumes to optimize inventory and logistics management.

5. Overall benefits for open-pit mines

The comprehensive application of AI and automation brings multiple benefits:

✅Improved production efficiency—automated equipment reduces downtime and optimizes resource utilization.

✅Cost reduction—reduces reliance on human labor and improves energy and equipment utilization.

✅Enhanced safety—reduces miners' exposure to hazardous environments and lowers accident rates.

✅Sustainability—Precise mining reduces resource waste, and drone monitoring supports environmental compliance.

Conclusion

Artificial intelligence and automation are fundamentally transforming the operational model of open-pit mines, making them smarter, more efficient, and safer. With the integration of 5G, the Internet of Things (IoT), and more advanced AI algorithms, the future of mining will evolve toward full autonomy, realizing the true “smart mine.” This transformation not only improves the industry's competitiveness but also lays the foundation for sustainable mining.