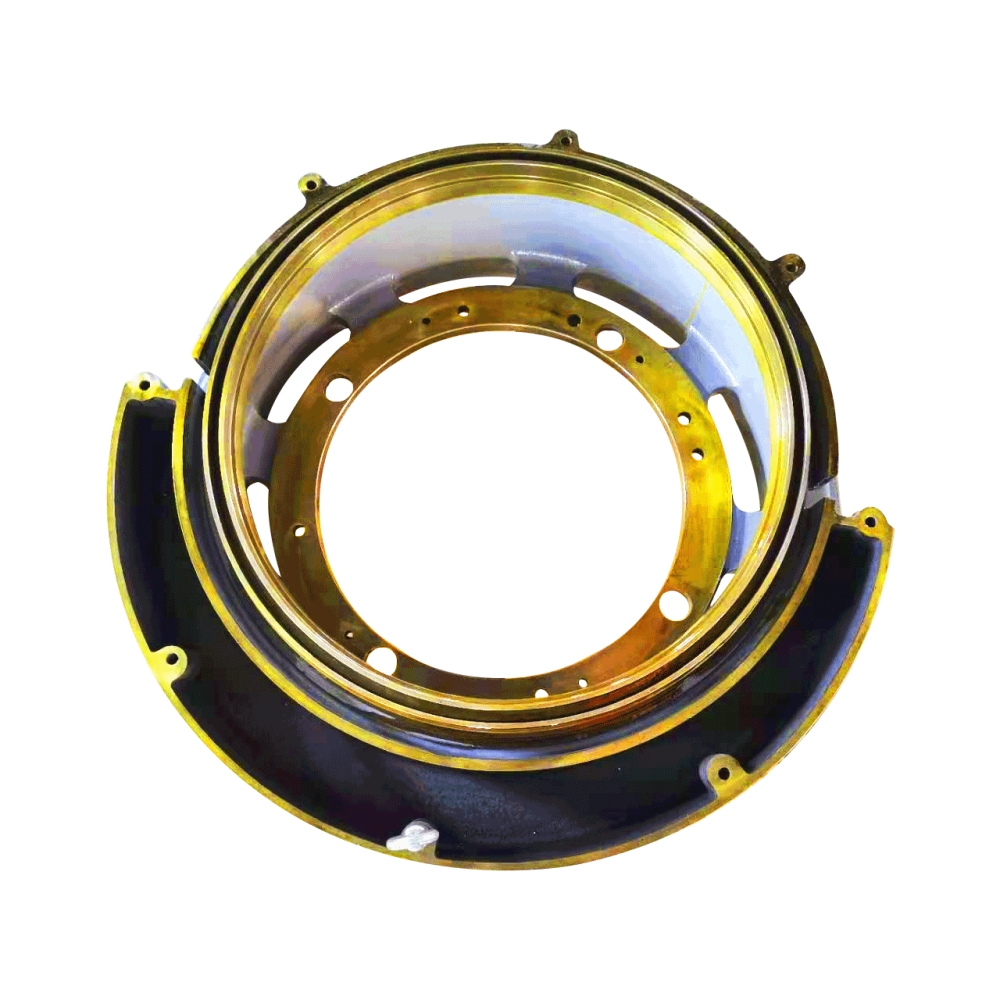

Cruhser Counter Weight

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Description

Description

A crusher counterweight is a component used in crushers, which are machines designed to break down large materials, like rocks and ores, into smaller, more manageable pieces. The counterweight is typically used to balance the machine’s rotating parts, such as the rotor or flywheel, to ensure smooth operation. Here's a breakdown of its importance and function:

Balance: Crushers often have rotating parts that generate significant forces during operation. The counterweight helps offset these forces and ensures that the machine operates smoothly without excessive vibrations. This is especially important in crushers like jaw crushers, cone crushers, and impact crushers, where the moving parts can exert significant mechanical forces.

Prevention of Excessive Wear: Without a counterweight, unbalanced forces can cause excessive wear on parts of the crusher, such as the bearings, shafts, and other mechanical components. The counterweight ensures that these forces are distributed more evenly, which can extend the life of the equipment.

Improved Performance: When the machine is well-balanced, it runs more efficiently and requires less energy to operate. This can lead to better overall performance, including higher throughput and lower fuel consumption or energy costs.

Custom Design: Depending on the crusher design and application, counterweights can vary in size, material, and location. They are typically made of heavy, durable materials like steel or concrete to provide the necessary mass.

Reduced Vibration and Noise: By balancing the rotational forces, counterweights help reduce vibrations, which can lead to less noise pollution and a more stable working environment.

In short, the counterweight in a crusher is crucial for balancing the mechanical forces and ensuring that the crusher operates smoothly and efficiently, while also protecting it from premature wear and failure.

Balance: Crushers often have rotating parts that generate significant forces during operation. The counterweight helps offset these forces and ensures that the machine operates smoothly without excessive vibrations. This is especially important in crushers like jaw crushers, cone crushers, and impact crushers, where the moving parts can exert significant mechanical forces.

Prevention of Excessive Wear: Without a counterweight, unbalanced forces can cause excessive wear on parts of the crusher, such as the bearings, shafts, and other mechanical components. The counterweight ensures that these forces are distributed more evenly, which can extend the life of the equipment.

Improved Performance: When the machine is well-balanced, it runs more efficiently and requires less energy to operate. This can lead to better overall performance, including higher throughput and lower fuel consumption or energy costs.

Custom Design: Depending on the crusher design and application, counterweights can vary in size, material, and location. They are typically made of heavy, durable materials like steel or concrete to provide the necessary mass.

Reduced Vibration and Noise: By balancing the rotational forces, counterweights help reduce vibrations, which can lead to less noise pollution and a more stable working environment.

In short, the counterweight in a crusher is crucial for balancing the mechanical forces and ensuring that the crusher operates smoothly and efficiently, while also protecting it from premature wear and failure.

Parts List