Circular vibrating screen

Manufacturer : MORETEC

Part number :

OEM Compatibility :

Category :Screening

Description

Description

Principle Overview

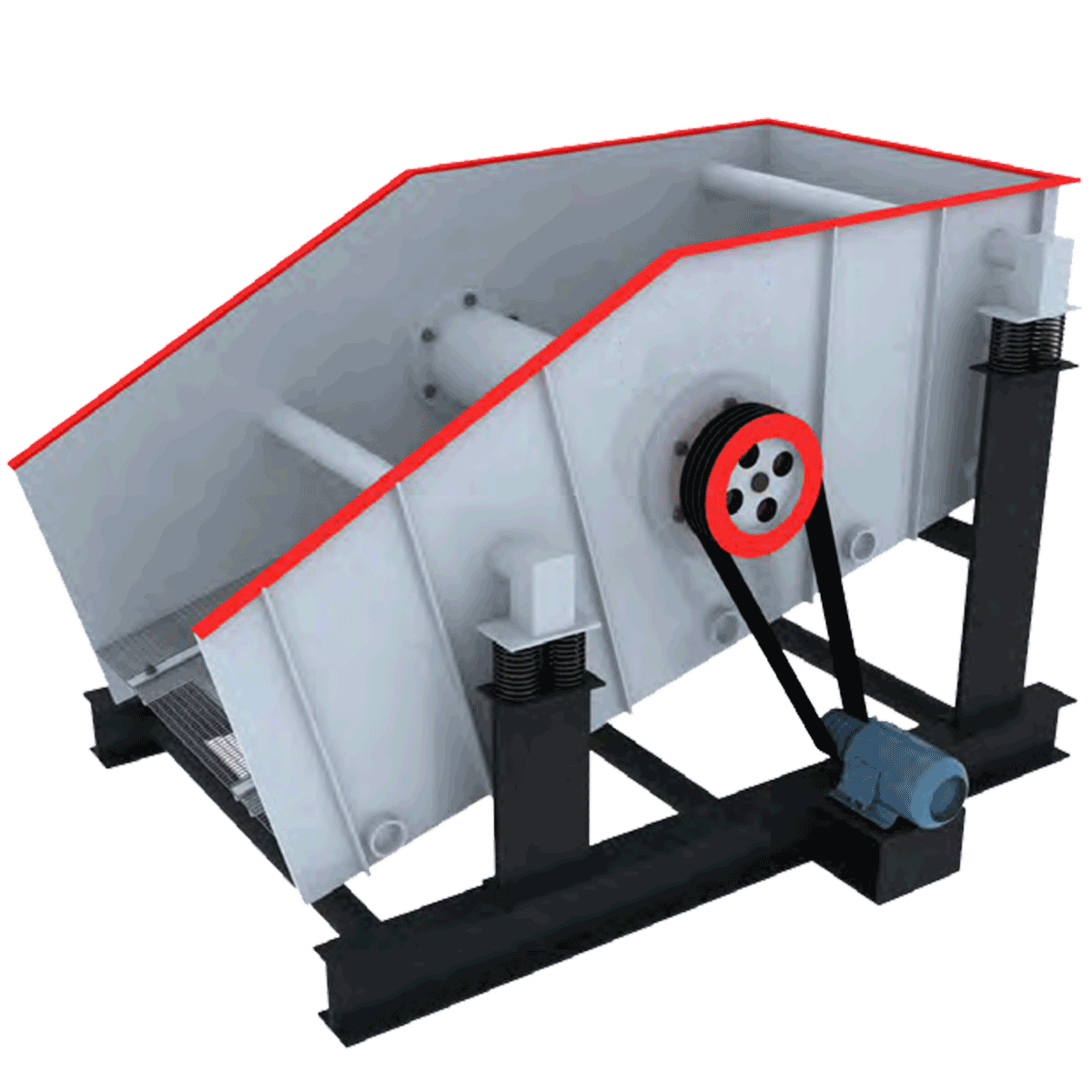

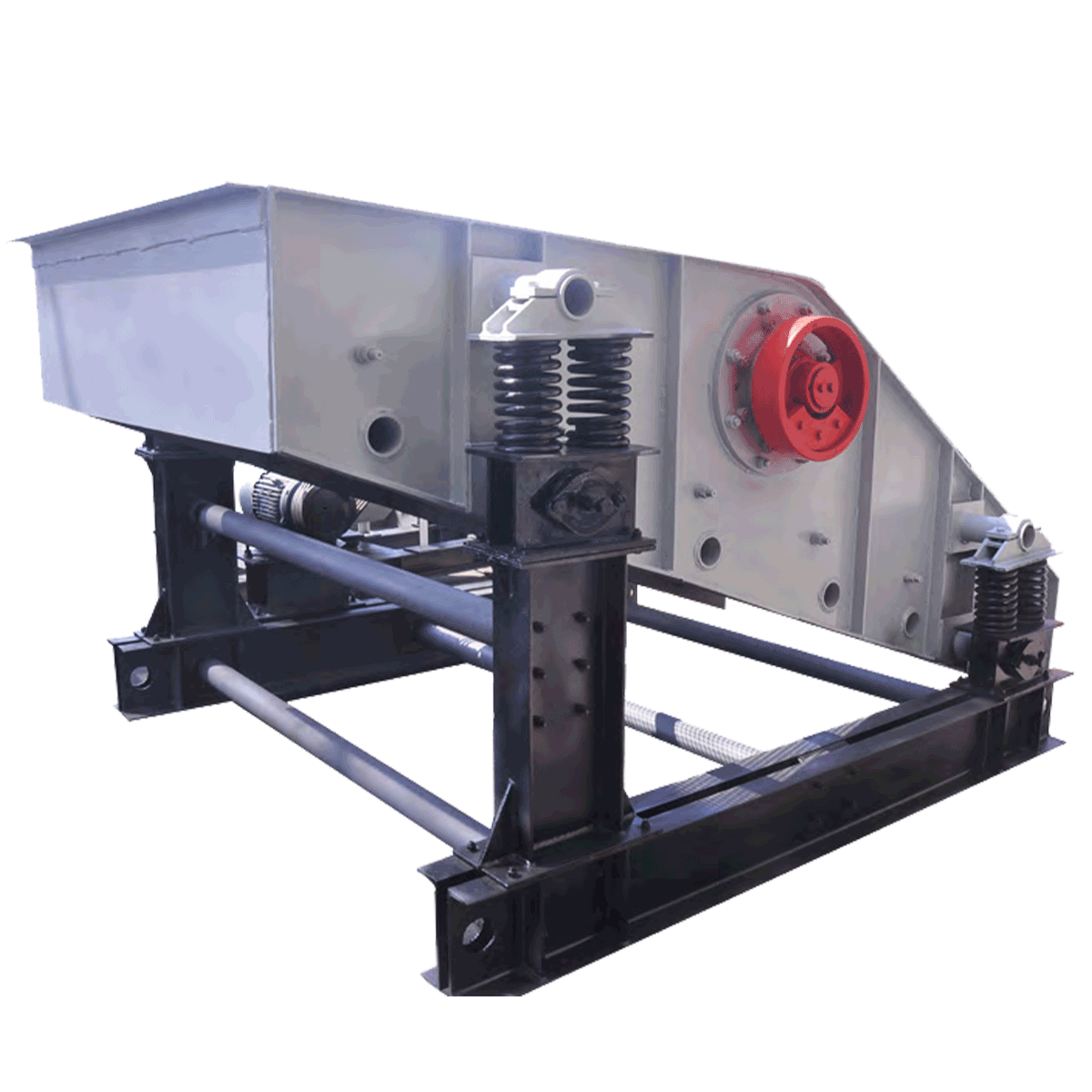

Circular vibrating screen is mainly composed of screen box, screen mesh, vibrator and damping spring. The vibrator is installed on the side plate of the screen box, and is driven by the motor through the triangular belt to produce centrifugal inertia force.

The vibrator is mounted on the side plate of the screen box and is brought by the motor through the triangle belt to rotate, generating centrifugal inertia force, forcing the screen box to vibrate, and the vibrating body, i.e. the screen box, has an approximate circular motion. In the meantime, the material smaller than the aperture of the screen surface falls through the sieve holes to the lower layer.

During the process, materials smaller than the aperture of the screen surface fall to the lower layer through the screen holes to become the under-screen material, and materials larger than the aperture of the screen surface are discharged from the discharge port after continuous jumping movement to finally complete the screening work.

Equipment features

◎ Circular vibrating screen is a new type of multi-layer and high-efficiency vibrating screen because its trajectory is similar to a circle, so it is called circular vibrating screen for short;

◎ Adopting eccentric shaft and eccentric block type vibrator, stable operation, high screening efficiency;

◎ The materials stuck in the screen holes can be jumped out to prevent the screen holes from being clogged;

◎ Adopting low-stress vibration-damping spring, low noise;

◎ Adopting super heavy-duty large clearance bearings, low running temperature and long service life;

◎ Adopting ring groove rivets and plate type screen box frame structure, high strength of screen frame structure;

Wear-resistant rubber screen mesh is available.

Scope of use

Suitable for mineral processing, coal processing, building materials, electric power, chemical industry and other departments for material classification, but also can be used for dewatering, desliming, demixing and so on.

Circular vibrating screen is mainly composed of screen box, screen mesh, vibrator and damping spring. The vibrator is installed on the side plate of the screen box, and is driven by the motor through the triangular belt to produce centrifugal inertia force.

The vibrator is mounted on the side plate of the screen box and is brought by the motor through the triangle belt to rotate, generating centrifugal inertia force, forcing the screen box to vibrate, and the vibrating body, i.e. the screen box, has an approximate circular motion. In the meantime, the material smaller than the aperture of the screen surface falls through the sieve holes to the lower layer.

During the process, materials smaller than the aperture of the screen surface fall to the lower layer through the screen holes to become the under-screen material, and materials larger than the aperture of the screen surface are discharged from the discharge port after continuous jumping movement to finally complete the screening work.

Equipment features

◎ Circular vibrating screen is a new type of multi-layer and high-efficiency vibrating screen because its trajectory is similar to a circle, so it is called circular vibrating screen for short;

◎ Adopting eccentric shaft and eccentric block type vibrator, stable operation, high screening efficiency;

◎ The materials stuck in the screen holes can be jumped out to prevent the screen holes from being clogged;

◎ Adopting low-stress vibration-damping spring, low noise;

◎ Adopting super heavy-duty large clearance bearings, low running temperature and long service life;

◎ Adopting ring groove rivets and plate type screen box frame structure, high strength of screen frame structure;

Wear-resistant rubber screen mesh is available.

Scope of use

Suitable for mineral processing, coal processing, building materials, electric power, chemical industry and other departments for material classification, but also can be used for dewatering, desliming, demixing and so on.

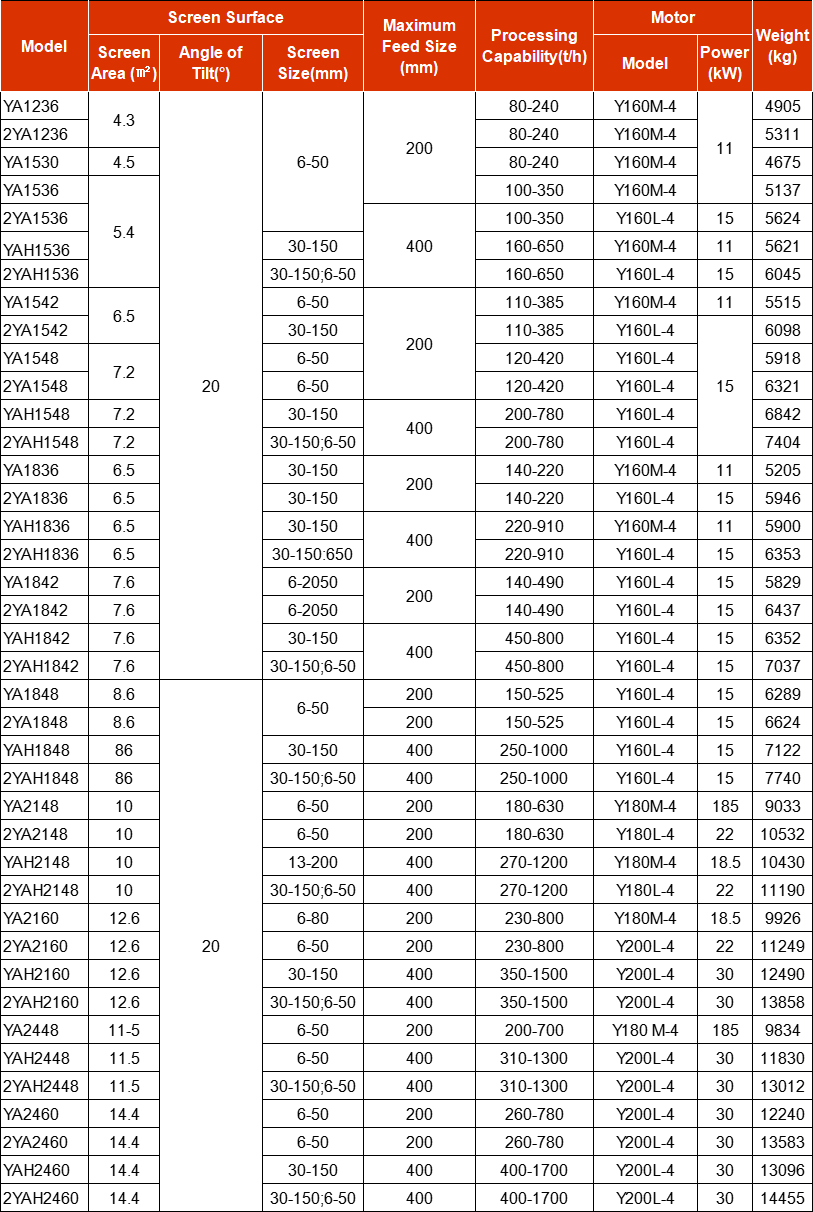

Parts List